Fusion power startups have long faced skepticism over whether the technology would ever work, but now that net-positive fusion power seems achievable, the focus has shifted to more practical questions. How can reactors be built affordably? How can maintenance be simplified? These questions could ultimately determine whether fusion energy becomes a viable industry or not.

Francesco Volpe, founder and CTO of Renaissance Fusion, has spent decades studying fusion. His experiences led him to create a unique fusion reactor design that’s catching the interest of investors. Renaissance Fusion recently raised €32 million in a Series A1 funding round, which will be used to build a demonstrator to prove the feasibility of the new design.

Fusion power promises large amounts of clean electricity from abundant fuel sources. Most fusion startups focus on either inertial confinement, where lasers compress fuel pellets to trigger fusion, or magnetic confinement, where powerful magnets contain plasma for long-duration reactions. Volpe’s work focuses on the latter and revolves around a specific type of magnetic confinement reactor known as a stellarator.

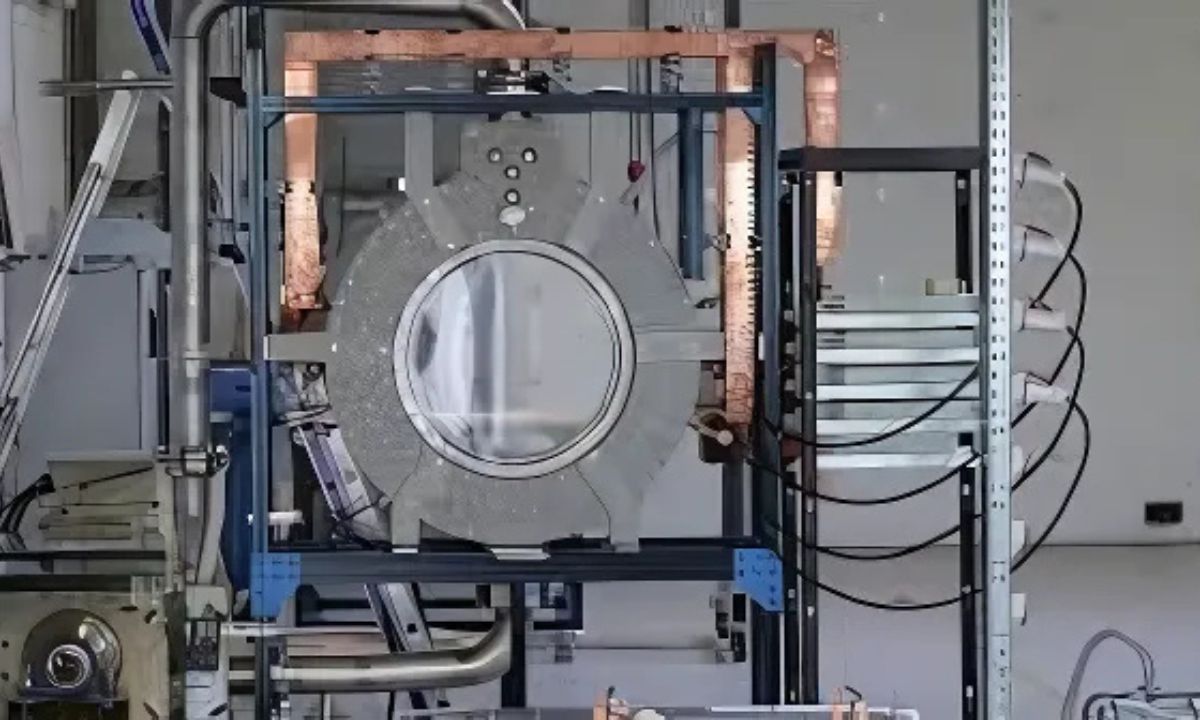

Stellarators are known for their complex, twisted shapes, which help stabilize plasma. Manufacturing these intricate shapes has been a challenge. Renaissance Fusion’s goal is to simplify this design. The company has developed a reactor that features segmented tubes decorated with etched lines that represent high-temperature superconducting (HTS) magnets. These magnets will shape the plasma inside the reactor while keeping the design simpler and more cost-effective.

Volpe’s approach is inspired by earlier research with a stellarator in Germany. By simplifying the reactor into actual cylindrical shapes rather than approximations, Volpe streamlined the design, incorporating flexible cables to create the necessary twists in the plasma’s shape. To further simplify the design, the team plans to use flat HTS magnets coated on the tubes, with a laser etching the required pattern onto the surface. The varying thickness of the magnets will create different magnetic fields, controlling the shape of the plasma.

Inside the reactor, Renaissance plans to use liquid lithium to protect the tubes from neutron radiation produced by the fusion process. This liquid will be electrically charged, creating a magnetic field to keep it in place and away from the plasma. The liquid will absorb some of the neutron energy, breed more fuel, and transfer heat to steam turbines to generate electricity.

Renaissance plans to have its first HTS “carpets” ready soon and a full demonstrator, complete with the reactor’s tubular HTS magnets and liquid lithium walls, by the end of 2026. The company aims to complete a full stellarator reactor by the early 2030s. Volpe believes this approach can ultimately provide a more cost-effective solution for fusion power.

The startup hopes the demonstrator will prove the concept, showing that each part of the design contributes to an efficient and affordable fusion reactor. With this innovation, Volpe is confident that they can turn fusion power into a practical reality.